| Part No. | |||

| TC-MM01 |

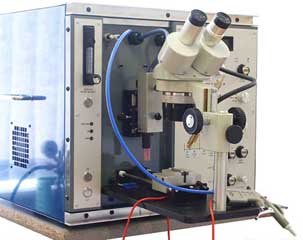

MI Thermocouple welding machine incorporates a new weld torch assembly and a new vice jaw arrangement for easier changing of thermocouple sizes.

A comprehensive tool kit and the extended manual is provided with all Welders. Key features include;

- Welds all Mineral Insulated thermocouples from 1.0mm to 6.0mm

- Fully automatic weld cycle under microprocessor control

- Both conductors and sheath closure weld carried out on one machine

- Removable Microscope included with optical light guide for maximum visibility

- Separate weld actions for conductors and sheath closure (CD & TIG)

- Automatic recharge on CD ready for next weld

- TIG weld has slope-up and slope-down functions for accurate weld control envelope

- Bench mounted

- Single phase supply

Physical Construction

The machine is constructed from 16 gauge Mild Steel, Epoxy powder coated on all inner and outer surfaces. The panels that make up the main case are bolted together by M6 bolts into captive nuts. There are no welded sections or self-tapping screws. The side panels have punched holes to allow airflow through the machine, which is assisted by an internal fan. Internal components are mounted on mild steel substructures, which can be removed for maintenance and repair. Two handles are provided on the sides of the machine, however, it is recommended that two people carry out any lifting or handling of the machine using approved lifting principles.

Specification

Electrical Power

The machine operates from a single-phase 220-250v-ac-50Hz supply and is rated at 2000VA. For countries using 110V 60Hz please specify at time of order.

Gas

The machine requires a supply of High purity Argon Gas. Use of any other gases e.g. Argon/Nitrogen, Helium etc will alter the characteristics of the weld arc. Advice should be sought before using special gas mixes.

Dimensions

The maximum outside dimensions of the machine, including the microscope and weld table, are:

500mm Wide

450mm High

750mm Deep

The bench footprint is

500mm Wide

480mm Deep