New Hydrolic Crimper from Thermalcomp Ltd.

New Hydrolic Crimper from Thermalcomp Ltd.

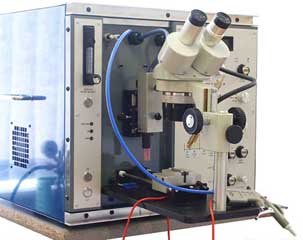

W60 Fine Wire Welder

| Part No. | |||

| W60 |

The W60 welder is designed for sensor manufacturers to

produce commercial grade thermocouple junctions, and by

users of large numbers of exposed junction thermocouples

such as test and development laboratories where multipoint

temperature sensing of test pieces is required.

| Part No. | |||

| TC-MM01 |

MI Thermocouple welding machine incorporates a new weld torch assembly and a new vice jaw arrangement for easier changing of thermocouple sizes…

| Part No. | |||

| TC-UCES-400 |

UCES-400 Ultrasonic Cable Stripping Machine uses powerful pulses of Ultrasonic energy to strip the sheath from mineral insulated cable…

| Part No. | |||

| TC-MM02 |

Precision MI Drilling Machine is designed to remove the insulation from the end of a prepared sample of M.I. cable in order to facilitate a complete welded measurement junction.

| Part No. | |||

| TC-FAULTLOC |

High Resistance Fault Locator helps you quickly find faults occurring in cables through damage caused in storage, transit or during installation…