Thermal Comp Ltd is an agile provider of machinery and parts for temperature sensor manufacturers based in the UK. In order to continue to lead the industry, while remaining as flexible as possible for our clients, we are happy to announce a widening of our products. These thermocouple and RTD manufacturing equipment items are of the highest quality and can be shipped to you quickly to ensure you are able to stay competitive during these difficult times.

New items available:

MI Cable Fault Locator

|

|

|

While the name indicates the use of this device, it doesn´t convey its quality enough. From its incorporated solid-state galvanometer with a backlight and adjustable sensitivity to its a high impact co-polymer, it is capable of accommodating all types of cables to better locate faults ensure you are able to resolve any issues that might arise in your manufacturing. The instrument design meets the requirements of cable testing and locating cable faults where the resistance ranges from zero to 100MΩ.

A lead acid battery and charger, including all the necessary cables and an illustrated comprehensive instruction manual are included.

|

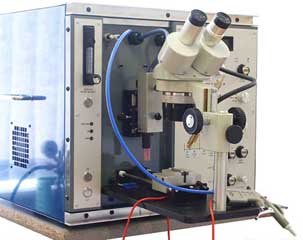

MI Thermocouple Welding Machine

|

|

|

The new and improved version of the MI Welding Machine includes various upgrades from its previous model from a new welding torch assembly to a new vice jaw arrangement allowing for simpler thermocouple size changing. The removable microscope is particulary good for maximizing visinility via the optical light. This machine can weld all mineral insulated thermocouples ranging from 1.0mm to 6.0mm. The fully automatic welding cyle is under the control of its microprocessor providing a better welding experience. These are just a few features of this machine; it is also has TIG weld slope-up and slope-down functions for accurate weld control, both conductors and sheath closure weld carried out on one machine, and much more. |

MI Cable Precision Drilling Machine

|

|

|

This machine has been designed for optimal precision, allowing for the easy removal of insulation from the end of a cable providing a complete welded measurement junction. This is accomplished by drilling the cable´s end to required depth. It is suitable for cables between 1.0mm and 6.0mm. All the needed drills, guides and collets are supplied for your convenience along with a complete instructional manual. A selectable footswitch control option, bench fixing kit, and comprehensive accessories are all included. Reaching speeds of up to 4000rpm, reducing preparation time, and other functionalities of the device have all helped to create this wonderful product we offer you at our competitive prices along with quick shipping. |

Ultrasonic MI Cable End Stripper

|

|

|

Using ultrasonic energy, this device strips the sheath cleanly from mineral insulated cables. With speeds ranging from seconds to milliseconds (depending upon the size of the cable) the machine achieves its job efficiently so that you are able to do the same. The device is accommodating of cables ranging from 1.0mm to 6.0mm. The only prior action required upon stripping is to ring through the sheath at the breakpoint (which can be up to 25mm from the cable´s end). Fortunately, this device also included a ringing tool as well as a pair of electronic side cutting pliers for your convenience. The Ultrasonic Stripper removes the sheath from a variety of cables such as stainless-steel sheathed cables, cupronickel sheathed cables, Inconel and other nickel based alloys as well. From single core to multi-core to even triaxial, the device is accommodating and gets the job done. This machine fortunately doesn´t require a compressed air, running directly off the mains supply. |

MI Cable End Warming Oven

|

|

|

In order to avoid the slow ingression of moisture into cables´ insulation, thereby lowering the insulation resistance, it is best to maintain the open end of a cable warm. Our cable end heater does this ensuring a high measurement integrity. Additional benefits of maintaining a warm cable to the welding process are:

-

-

- Improved breakdown of argon gas creating a smoother, speedy burn.

- The reduced risk of pressure differentials within the weld that cause the rising of molten metal.

- Increased resistance and capacitance preventing the corruption of the components used to start a weld.

-

-

|